33/19, First floor,1st Main Rd, Jai Nagar, Arumbakkam, Chennai, Tamil Nadu 600106

Call us for inquiry : +91 90926 46761

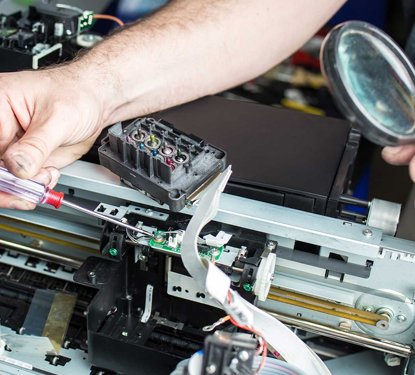

Printer Service Training

Struggling to find a job?

Take the first step with expert technical training